Glyd Ring® RG23 is produced with an interference fit which together with the squeeze of the O-Ring ensures sealing effect even at low pressures. At higher system pressures, the O-Ring is energized by the fluid, pushing Glyd Ring® against the sealing face with increased force. Besides good static sealing the wide, shallow chamfers provide generous lubrication of the dynamic contact area in reciprocating applications. Available in Turcon® or Zurcon® materials. The O-Ring is not included with this item.

Rod/GlydRing®/Turcon®:

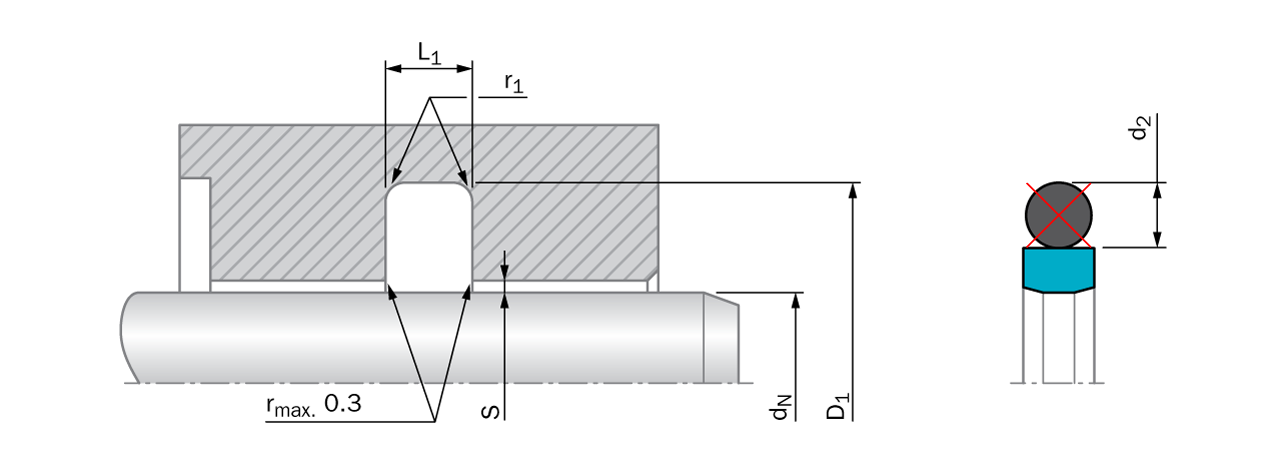

Groove Diameter Outside65.1 mm

Ring Width5.9 mm

Signature StandardRGB300500-M12

Quality (10th Digit)-

TSS Article Number (3 to 9)B300500

Type of Article0

Groove Diameter Inside50 mm

Root Ring Inside Diameter49.1 mm

Root Groove Inside Diameter50 mm

Root Groove Outside Diameter65.1 mm

Root Groove Thickness7.55 mm

Root Groove Width6.3 mm

Article GroupRG

Legacy ID from KOM2RGB300500-M12

Root Ring Outside Diameter56 mm

Root Ring Thickness3.45 mm

Ring Thickness3.45 mm

Groove Thickness7.55 mm

Groove Width6.3 mm

Root Ring Width5.9 mm

Seals Helsingor Material Class:

Seal Tube OD Tolerance Max16 mm

Seal Tube ID Tolerance Min-16 mm

Seal Tube OD Tolerance From57.3 mm

Seal Tube ID Tolerance Max-1.3 mm

Seal Tube OD Tolerance Min1.3 mm

Ring Diameter Outside56 mm

Seal Tube OD Tolerance To72 mm

Seal Tube ID Tolerance To47.8 mm

Seal Tube ID Tolerance From33.1 mm

Ring Diameter Inside49.1 mm

Class Dependencies200000071372

Material Number200000071372

Compound Type110

Compound codeM12

Material Information for the product(s) on this page

M12

Basic Material:

PTFE

Filler:

Virgin PTFE compounded with Turcon®, mineral fibre and additives

Colour:

Dark Grey

Commercial Description:

Turcon® M12 is a modern compound and the new standard industrial material. A development of thorough benchmarking and performance testing, Turcon® M12 offers low friction, high wear resistance and costs on par with standard bronze-filled compounds. This material is designed to be the first choice for seals used with linear motion, replacing standard (medium-filled) industrial bronze-filled compounds. Used in article numbers ending in M12N and M12V.

English

English