Trelleborg Double Delta® combines the flexibility and response of O-Rings with the wear and friction characteristics of the Turcon® materials in dynamic applications. The double acting performance of the seal follows from the symmetrical cross section which allows the seal to respond to pressure in both directions. Initial contact pressure is provided by radial compression of the O-Ring. When the system pressure is increased the O-Ring transforms this into additional contact pressure, the contact pressure of the seal is thereby automatically adjusted so sealing is ensured under all service conditions.

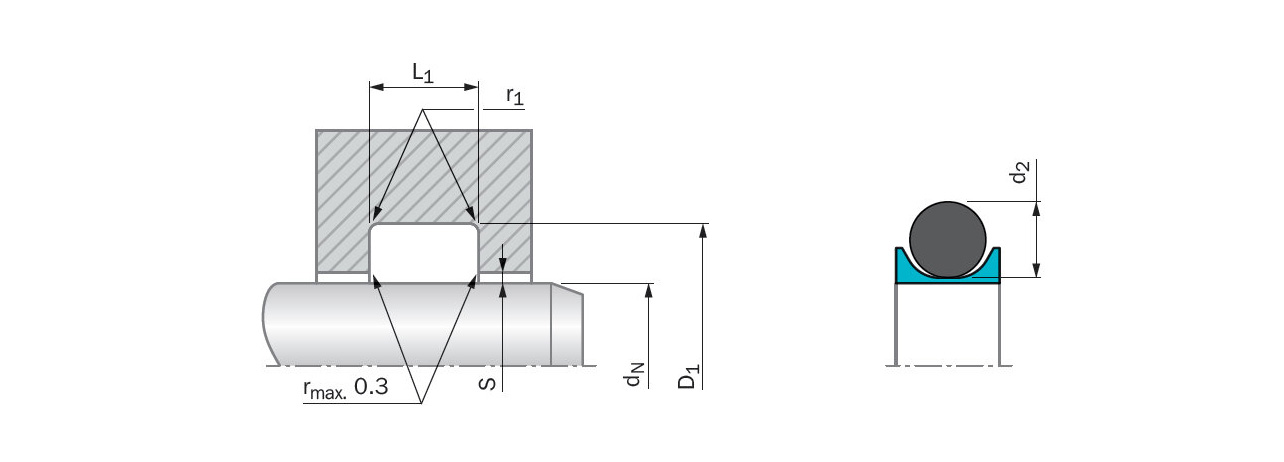

Installation Dimensions:

Rod Diameter, dN h922 mm

Groove Diameter, D1 H928.2 mm

Groove Width, L1 +0,24.8 mm

Material Properties:

Material TypePTFE/FKM

Seal Capabilities:

Min. Temperature-10 °C

Max. Temperature200 °C

Speed max.15 m/s

Pressure max.35 MPa

O-Ring:

O-Ring Size21.82 x 3.53 mm

O-Ring TSS Article No.ORAR00212

Quality & Norms:

Correspond to recommendation of ISO 3320yes

Material Information for the product(s) on this page

V7

Colour:

Green

Basic Material:

FKM

Commercial Description:

A 70 durometer FKM. FKM is an elastomer material known especially for its non-flammability, low gas permeability and excellent resistance to ozone, weathering, and ageing. The operating temperatures of the fluorocarbon rubber range between -20 °C and +200 °C (for a short period of time up to +230 °C). FKM is also often used with mineral based oils and greases at high temperatures. Used as an energizer in T46V and M12V

M12

Colour:

Dark Grey

Basic Material:

PTFE

Filler:

Virgin PTFE compounded with Turcon®, mineral fibre and additives

Commercial Description:

Turcon® M12 is a modern compound and the new standard industrial material. A development of thorough benchmarking and performance testing, Turcon® M12 offers low friction, high wear resistance and costs on par with standard bronze-filled compounds. This material is designed to be the first choice for seals used with linear motion, replacing standard (medium-filled) industrial bronze-filled compounds. Used in article numbers ending in M12N and M12V.

English

English