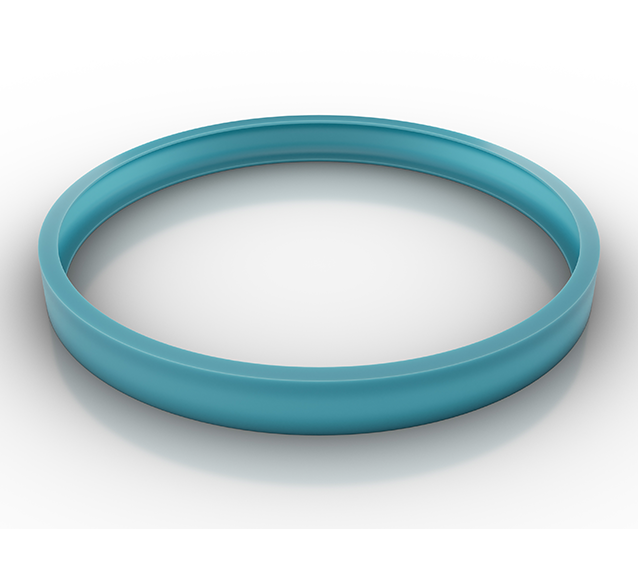

The Double Delta® is a double-acting PTFE sealing element which is energized by an elastomer O-Ring. The Double Delta® seal can be fitted in existing O-Ring grooves (US standard AS 568 A, MIL-P-5514) and it demonstrates good friction properties, stick-slip-free starting and excellent dry running. The Double Delta® is used in light and medium duty industrial hydraulics. Available in Turcon® or Zurcon® materials. The O-Ring is not included with this item.

Pist/DoubleDelta®Turcon®:

Groove Diameter Outside100 mm

Ring Width6.7 mm

Signature StandardPDD301000-M12

TSS Article Number (3 to 9)D301000

Quality (10th Digit)-

Type of Article0

Root Ring Inside Diameter96.65 mm

Root Groove Inside Diameter90.6 mm

Root Groove Outside Diameter100 mm

Root Groove Thickness4.7 mm

Root Groove Width7.1 mm

Groove Diameter Inside90.6 mm

Article GroupPD

Root Ring Length0 mm

Legacy ID from KOM2PDD301000-M12

Root Ring Outside Diameter100.45 mm

Root Ring Thickness1.9 mm

Root Ring Width6.7 mm

Ring Thickness1.9 mm

Groove Thickness4.7 mm

Groove Width7.1 mm

Ring Length0 mm

Seals Helsingor Material Class:

Seal Tube OD Tolerance Max50 mm

Seal Tube ID Tolerance Min-50 mm

Seal Tube OD Tolerance From102.45 mm

Seal Tube ID Tolerance Max-2 mm

Seal Tube OD Tolerance Min2 mm

Ring Diameter Outside100.45 mm

Seal Tube OD Tolerance To150.45 mm

Seal Tube ID Tolerance To94.65 mm

Seal Tube ID Tolerance From46.65 mm

Ring Diameter Inside96.65 mm

Class Dependencies200000048776

Material Number200000048776

Compound Type110

Compound codeM12

Material Information for the product(s) on this page

M12

Basic Material:

PTFE

Filler:

Virgin PTFE compounded with Turcon®, mineral fibre and additives

Colour:

Dark Grey

Commercial Description:

Turcon® M12 is a modern compound and the new standard industrial material. A development of thorough benchmarking and performance testing, Turcon® M12 offers low friction, high wear resistance and costs on par with standard bronze-filled compounds. This material is designed to be the first choice for seals used with linear motion, replacing standard (medium-filled) industrial bronze-filled compounds. Used in article numbers ending in M12N and M12V.

English

English