Rectangular cross-section. Consists of two spiral windings which are cut at the ends at an angle of 30° or 45°. Designed for static and dynamic use, but when used in a dynamic application they should be used for reciprocating movements only. Compensates for large temperature changes and tolerances due to screw-like elongation and contraction. Material: PTFE

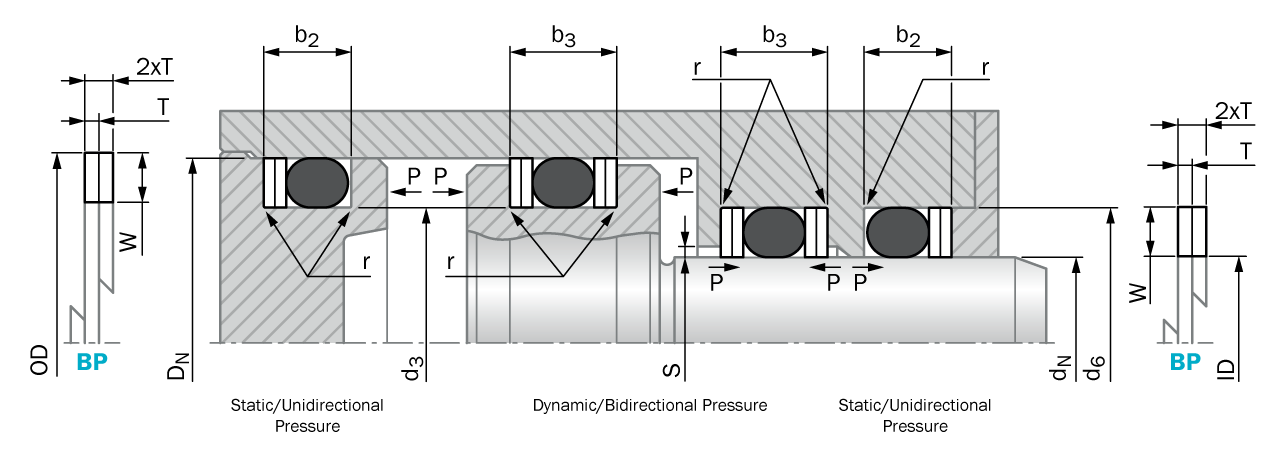

Installation Dimensions:

Bore Diameter DN H8 // Groove Diameter d6 H955 mm

Groove Width b2 +0.256.2 mm

Groove Width b3 +0.257.6 mm

Radius, r ±0.20.25 mm

Groove Diameter d3 h9 // Rod Diameter dN f748.8 mm

Material Properties:

Maximum Operating Temperature120 °C

Minimum Operating Temperature-45 °C

Hardness Nominal40

Hardness Tolerance+/- 5

Hardness UnitShore A

Material TypePTFE

Tensile Strength31 MPa

Elongation at break300 %

Seal Capabilities:

Min. Temperature-200 °C

Max. Temperature260 °C

Pressure max., static use250 MPa

Pressure max., dynamic use, reciprocating25 MPa

Pressure max., dynamic use, oscillating or rotating15 MPa

Internal Sealing (Rod) and External (Bore) sealing:

Back-up Ring dimensions OD x W x T55.0 x 3.10 x 0.70 mm

O-Ring TSS Part No.ORAR00225

O-Ring dimensions d1 x d247.22 x 3.53 mm

Material Information for the product(s) on this page

PT00

Colour:

White to Offwhite

Basic Material:

PTFE

Commercial Description:

Unfilled PTFE. This material is standard for back-up rings. Unfilled PTFE helps prevent extrusion in low- to medium-duty applications where an O-ring used by itself would not be suitable.

English

English